Aws Cwi Things To Know Before You Buy

Aws Cwi Things To Know Before You Buy

Blog Article

Aws Cwi Fundamentals Explained

Table of ContentsLittle Known Questions About Aws Cwi.6 Easy Facts About Aws Cwi ShownWhat Does Aws Cwi Do?Our Aws Cwi IdeasAws Cwi - The Facts

Third-party quality assurance assessment of steel fabrication fixate welding assessment, along with assessment of bolting and painting of architectural steel. KTA's steel inspectors give Quality assurance (QC) examiners to supplement producer's/ professional's in-house QC staff and on jobs that mandate preserving the services of a certified assessor (e.g., CWI) used by an independent inspection firm.Examiners carry out visual evaluations of material for conformance with the accepted specifications, strategies and codes, as well as confirmation of Certified Material Examination Records (CMTR) for products used. Materials and elements are observed at key factors along the manufacturing procedure in both steel mills and steel construction shops. KTA's certified welding assessors also witness welder and welding treatment certification tests as suitable to the scope of the project.

Steel fabrication examination services also routinely consist of performing non-destructive screening (NDT), additionally called non-destructive examination (NDE), including Magnetic Bit Evaluating (MT), Ultrasonic Screening (UT) and Fluid Penetrant Testing (PT) (CWI Welding Inspector). Assessments happen in steel mills and fabrication stores throughout the United States and on-site in the area and consist of all ranges of structures including bridges, stadiums, buildings, towers, posts, and sign structures

The Aws Cwi Diaries

KTA gives examination services for the manufacture of bridge girders, bearings, grid deck, sign frameworks, light and traffic posts, pedestrian bridges, and other highway components. KTA additionally gives these solutions for construction of architectural steel for structures, storage tanks and pipelines. KTA's examination solutions consist of finish assessments covering surface preparation, painting, galvanizing, and metalizing.

KTA's viewpoint is to respond promptly to customers' requirements, match the right inspector to the job, and offer the requisite paperwork. KTA has the assistance personnel to give technological consulting to the area employees and to the client. KTA has professionals offered to speak with on welding, NDT and finishes.

Come sign up with an amazing group in an amazing, fast paced, and ever-growing industry! We are looking for a CWI's and/or NDT Degree II accredited Welding Inspectors from in and around the Lithia Springs, GA location!

Facts About Aws Cwi Uncovered

Ideal candidate will have high purity piping inspection experience. CWI's and NDT Level II's extremely urged to use.

Pro QC's third-party welding inspection solutions include: Paper Evaluation Witness Inspections Visual Inspections Dimensional Inspections Non-Destructive Testing (NDT) Others Our welding inspection records are provided within 24 hours and record all assessment factors appropriate to quality, consisting of all determined weld flaws and electronic photos (Certified Welding Inspector) (https://us.enrollbusiness.com/BusinessProfile/6859290/AWS%20CWI). Pro QC's group of inspectors provides third-party welding evaluations around the world, in China, India, Indonesia, Malaysia, Thailand, Vietnam, Singapore, South Korea, Turkey, UAE, Jordan, Egypt, South Africa, Morocco, Algeria, Tunisia, France, Germany, Italy, Czechia, Hungary, Spain, Sweden, Portugal, the Netherlands, Denmark, Norway, Finland, Belgium, the UK, Serbia, Greece, Romania, Bulgaria, Ukraine, Slovenia, Slovakia, Poland, Croatia, Russia, Lithuania, the USA, Mexico, copyright, Brazil, Peru, and many more countries

Assessment of the welding job is vital for proper quality When your business is taking care of significant tasks with needs for third event independent welding examination, we offer outstanding welding witness assessment solutions to confirm that welding has been executed according to the majority of used welding requirements and requirements. AQSS executes welding inspection solutions for clients from a range of markets.

Excitement About Aws Cwi

Not adhering to appropriately qualified welding procedures frequently leads to a weld of below average high quality, which can enhance the fabrication's probability of failing under desired service conditions. By evaluating for flaws, our assessors can aid customers make sure that their welds fulfill relevant standards of high quality guarantee (Weld Inspection). Weld examinations are carried out for several reasons, the most typical of which is to identify whether the weld is of ideal quality for its desired application

Our welding inspectors have the needed qualifications with years of experience with examination and are familiar with many used welding criteria and specs. AQSS has actually CWI accredited examiners.

The 15-Second Trick For Aws Cwi

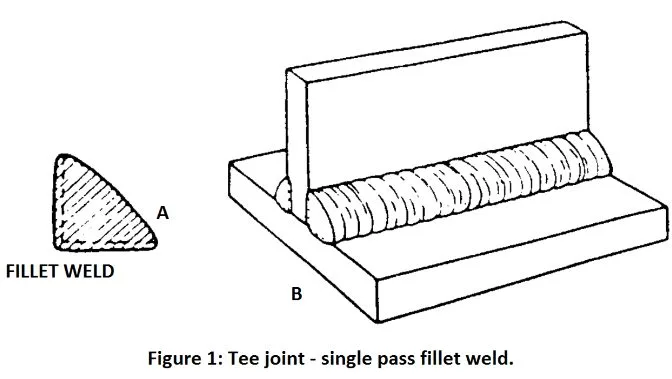

Weld examination of laser and electron beam welded components usually complies with 3 distinctive courses: visual inspection; damaging testing; and non-destructive screening (NDT). includes taking a look at a weld with the nude eye and/or with some level of zoom. Typically, our inspectors are looking for splits, pits, surface area pores, undercut, underfill, missed joints, and various other facets of the weld.

Samples can additionally be taken at periods throughout the production process or at the end of the run. Harmful testing examples are specifically cut, machined, ground, and brightened to a mirror-like finish. An acid etch is after that applied to visually highlight the weld, and the sample is then evaluated under a microscopic lense.

Report this page